Defect of the Month

Back to AGR's Library

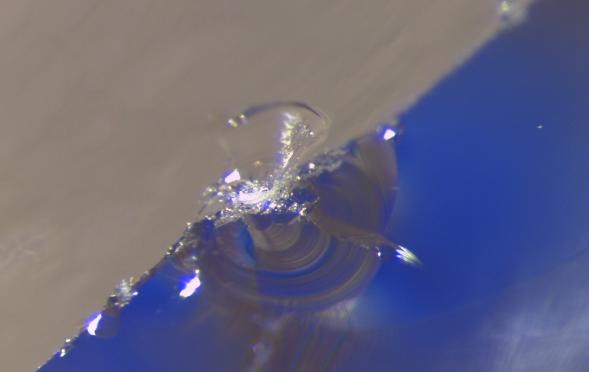

When a hard, pointed object smashes into a glass surface, it’s a bit like an ice pick biting into a frozen pond. Pronounced ripple markings extend downward from the impact site, while crushed glass marks the origin of the damage on the surface. Point contact damage is a sign of rough handling, and can be caused by glass fragments from a prior breakage event or exposed metal points somewhere in the factory. Lastly, the blue color in this image is not the actual glass color, but is just a reflection from an object used to enhance visibility of the surface markings.

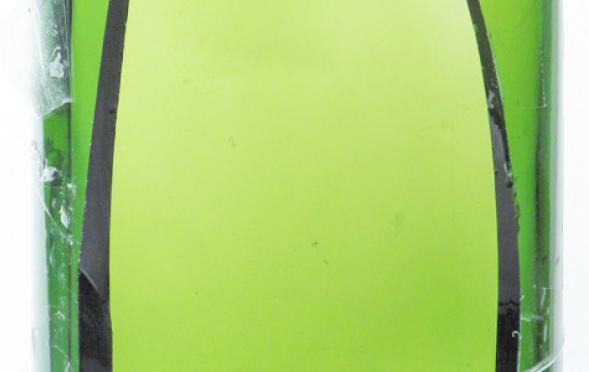

Stones and cord in glass can sometimes go hand-in-hand. This container has a large refractory stone in the heel that also created a highly stressed cord in the sidewall. Although a polarimeter cannot reliably detect cord when the bottle is viewed through the sidewall, high magnitude cord stress can sometimes be seen in this manner. The small knots of stress within the cord are additional particles of the stone created as it dissolved within the melt.

A triangle of magenta, a slash of yellow, and a gentle gradient of blue would fit right into an exhibit of minimalistic abstract artwork. But the scientific content of this image is anything but minimal. Ring sections of glass are routinely examined for cord stresses using polarized light microscopy per ASTM C978. This particular ring section shows a strong tension cord on the exterior surface of the container, which appears bright yellow in this orientation. The magenta triangle is the background color, and the blue gradient is compression induced in the glass by the cord. High magnitude tensile stress on the exterior surface is a concern for containers, especially those that contain a carbonated product. Breakage in the pasteurizer or delayed breakage in the warehouse are the most common problems due to cord.

This typical lehr crack consists of fracturing in the bottom and sidewall sections of a wine bottle that was extended in the annealing lehr. Lehr cracks typically originate at moderately severe (or worse) flaws created upstream of the lehr. Most commonly, the flaw or damage is located on the bearing surface which then extends into a fracture due to the thermal stresses produced during the annealing process. A common feature of lehr cracks is a series of dwell marks on the fracture surface indicating that the fracture extended to a certain point and then paused before being acted upon again and extending further. Thick bottomed items such as sparkling wine bottles are more susceptible to lehr crack formation. Darker glass and thick bottoms can also lessen the likelihood that lehr cracks are identified through inspection. Lehr cracks are strength-reducing defects and may fracture the container immediately upon handling.

Pagination

- Previous page

- Page 2

- Next page