Annealing

Quantitative determination of stress levels resulting from annealing, cord or tempering. An improperly annealed glass item exhibits elevated tensile stress levels, which if excessive can produce spontaneous failure of the item. In addition, when loads such as internal pressure or thermal shock are applied to improperly annealed items, the two stress fields can combine to lead to product failures.

We have the expertise to perform detailed analysis of residual permanent stresses from annealing and can assist you in determining the proper course of action when these stresses are excessive. Experiencing delayed or warehouse breakage is a costly way to learn that the annealing stresses in an item are unacceptably high. Therefore, the performance of an annealing evaluation by itself or in combination with a comprehensive test protocol is a prudent step towards ensuring quality glassware.

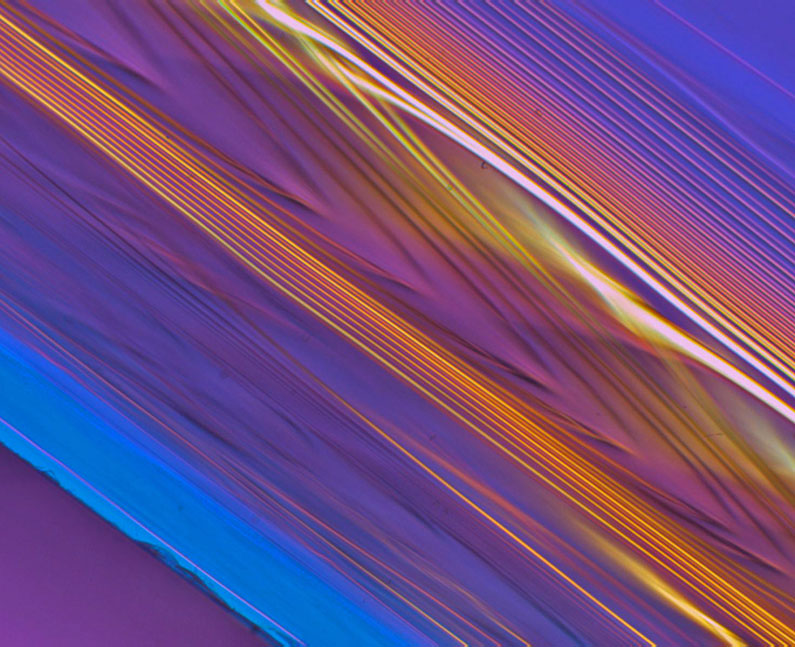

Cord

Also known as ream, striae, or "cat scratch", cord is a streak of glass with a composition different from the bulk. These defects can compromise the performance and appearance of a container. We can perform quantitative measurements of cord stress, as well as identify the cord composition;

Tempered Ware

When increased tensile strength glass is required, thermally tempering the item is one method to achieve this goal. Properly tempered glass must have layers of compression on outside glass surfaces, with a buried layer of tension stress within the interior of the glass thickness. If the item fails, tempered glass offers the added safety of dicing (breaking into relatively uniform chunks of glass rather than sharp shards).