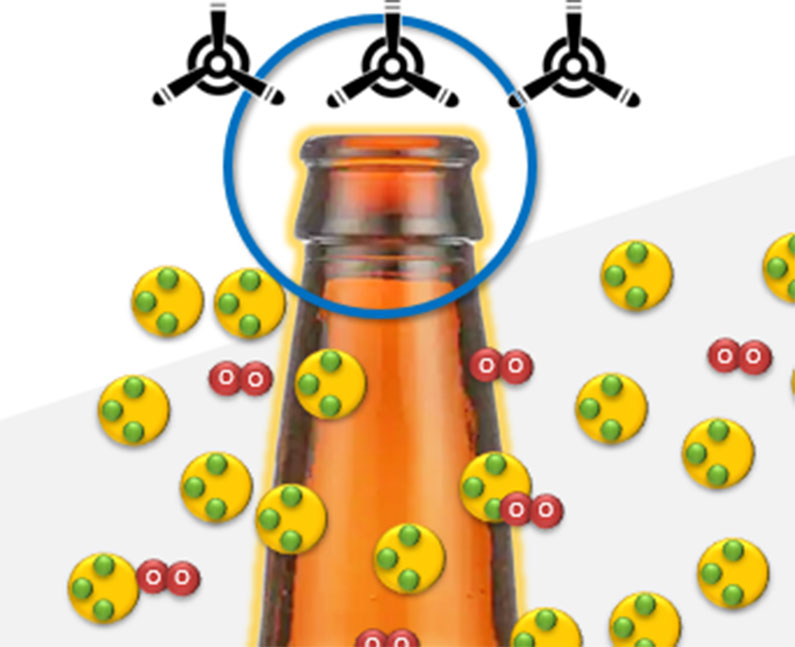

Analysis of surface coatings to ensure proper lubricity, identify label adhesion problems or product contamination issues. The use and application of coatings with glass can lead to a number of unique problems, such as adhesion problems, product contamination, and optical effects like iridescence and hazing.

The practice of coating glass surfaces has become an essential part of many of the glass products used today, from thin films on windows to filter UV and infrared light, to advanced conductive coatings used in flat panel displays. In the U.S. glass container industry, more than 95% of all glass containers (36 billion/year) are produced with one or more lubricious coatings designed to protect the surface and prevent strength loss; worldwide, the number is over 180 billion coated glass containers per year.

We have a full range of analytical capabilities in the field of glass surfaces and coatings, along with a wealth of knowledge and experience to employ them. Our primary area of expertise-developed from more than half a century in the industry-is coatings on glass containers. This area includes protective metal oxide and polymer coatings (commonly called the "hot end" and "cold end" coatings) routinely applied for the purpose of lubricity and scratch resistance, as well as other decorative and functional coatings used in the packaging industry. Some of the problems that can arise from bottle coatings include:

- Poor performance on filling lines, including the inability to pass bottles through the line (also called "bridging" or "seizing") and excessive damage from high friction due to poor surface protection

- Label adhesion, ink beading, and other decorating problems due to excessive or improper coatings

- Interactions with caps or closures, such as rusting or removal torque problems

- Internal contamination with coating or decorative materials, leading to poor product appearance and concerns with taste or consumer health

We employ state-of-the-art techniques such as reflectometry, polarimetry, scanning electron microscopy (SEM), x-ray spectroscopy, and infrared spectroscopy (FTIR) techniques to characterize and identify coatings on glass. Our test capabilities include physical, optical, and chemical evaluations of coatings, as well as performance under simulated conditions of the filling line, pasteurizer, or caustic wash.

If you are experiencing glass manufacturing or usage problems, and suspect that glass coatings may be a factor, contact us today. There is no upfront charge to speak to one of our experts, and we would be more than happy to discuss how our services may be able to benefit you. If testing is pursued, a formal report-written in plain language-will be prepared at the end summarizing our procedures, results, conclusions, and recommendations for eliminating the problem. Pricing is based on time, materials, and equipment usage, and a cost-free quote for service is available upon request. If necessary, American Glass Research personnel are available for on-site inspection and consulting as well.