We are pleased to announce the appointment of Ralph Elder to lead Agr International’s worldwide sales and marketing. This appointment is a continuation of Agr’s multi-year plan to strengthen and expand its sales and service organizations, while continuing to partner and support the distinct needs of customers throughout the world.

Ralph will assume the position of Vice President of Sales and Marketing. In this role, he will oversee all sales, marketing and business development related activities throughout the Agr organization.

Latest News

Alina Chronowska has joined out testing team as a Senior Scientist in our Delft, the Netherlands testing laboratory. Please join us in welcoming her to AGR.

She has over 17 years of glass packaging experience and has a deep understanding of the relationship between glass packaging design, production, processing conditions, quality and performance characteristics. For over 10 years she has been actively involved in the development and implementation of new containers for a major glass manufacturer.

Alina holds a Master of Science in Mechanical Engineering from the Silesian University of Technology in Gliwice, Poland. Contact Us if you have any questions for her about your glass packaging.

We recently traveled to Mombasa, Kenya to provide services to Milly Glass Works.

The services included the presentation of our Fracture 1: Testing and Breakage Diagnosis of Glass Containers” training seminar by Bill Slusser (Director of Research) and Peter de Haan (Manager, Research Services -Europe).

In addition, an in-depth survey of their glass manufacturing process was undertaken by Mr. de Haan in order to identify optimization and refinement opportunities.

Milly Glass Works has been in business since 1954 and is a prominent manufacturer of glass containers and tableware in the East Africa region.

Contact Us if you would like us to visit your facility for training or to help identify optimization and refinement opportunities.

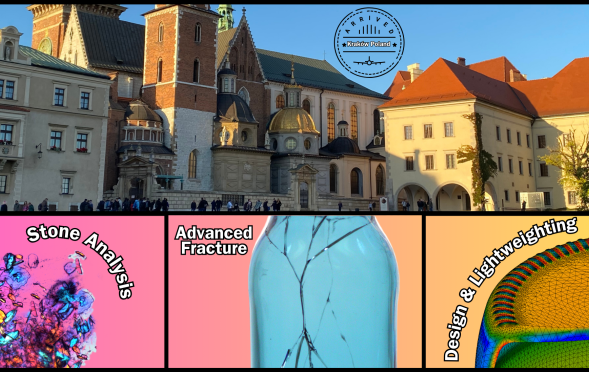

This Fall, in Krakow, Poland we will conduct two in-person seminars:

- Stones in Glass: Analysis and Identification, Oct 2 – 4

- Fracture 2: Advanced Breakage Diagnosis, Oct 7 – Oct 10

Seats are limited. Learn more about each one or register in our Training Catalogue.

Lake Ammersee, Germany is the site for our two open enrollment Training Seminars coming up in September:

- Fracture 3: Master Class Sep. 3-6

- Fracture 1: Testing & Breakage Diagnosis Sep. 9-11

Enjoy learning at this beautiful location. See our full Fall International Training Schedule Including Krakow, Butler, PA and Bangkok.

Last week (w/o Jun 10) Dr. Brandon Aldinger and Director of Research, Bill Slusser, traveled to East Africa to conduct our “Fracture 1: Testing and Breakage Analysis” training seminar at Kioo Limited, which is located in Dar Es Salaam, Tanzania.

Kioo Limited is the largest glass plant in East Africa and the only glass container manufacturer in Tanzania. Kioo supplies multiple beverage, beer and liquor customers along with some food jars. They currently run two furnaces of flint glass, green glass and amber glass.

Interestingly, Kioo was established in 1963, the exact same year that our founder Dr. Frank Preston, transitioned his Preston Labs into American Glass Research.

Pagination

- Page 1

- Next page