How should pharmaceutical glass suppliers and drug manufacturers evaluate new technologies for vials and syringes? Learn more in our free upcoming e-Seminar. AGR’s

Dr. Brandon Aldinger will be conducting a free 30-minute e-Seminar May 30 at 9 AM EDT, on “Applying Glass Fractography to the Evaluation of Novel Glass Parenteral Technologies”.

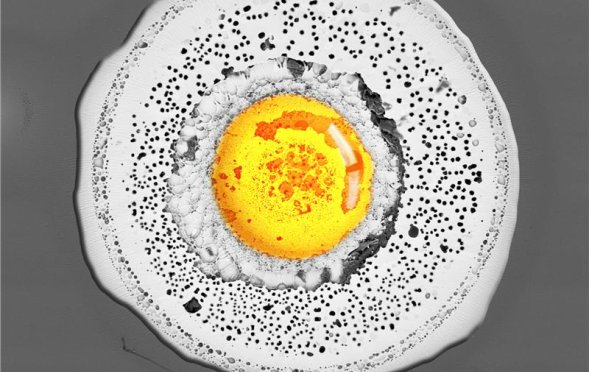

From flaw identification to breaking stress measurement, fracture analysis can yield insights into technology development, line handling, and flaw severity for the next generation of pharma packaging. If you need help with your pharmaceutical glass container breakage, please join in our free e-seminar with Dr. Aldinger. Learn more in our just released Q2 e-News Blast and how to join the livestream.